bending fatigue test|rotating bending fatigue : trade Rotating bending fatigue testing of small diameter solid round wire is possible by looping a specimen of predetermined length through an arc of 90° to 180°. The bending strain . Watch Amateur Granny Big Tits porn videos for free, here on Pornhub.com. Discover the growing collection of high quality Most Relevant XXX movies and clips. No other sex .

{plog:ftitle_list}

Resultado da Charlie Brown e o Dia de Ação de Graças avaliado por quem mais entende de cinema, o público. Faça parte do Filmow e avalie este filme você também.

We explored the bending fatigue behavior of various polymer films (PEN, PET, PVC, PC, COP, and PS) using the newly developed bending fatigue tester, which can precisely control test conditions and quantify the radii of . Rotating bending fatigue testing of small diameter solid round wire is possible by looping a specimen of predetermined length through an arc of 90° to 180°. The bending strain .COMMON FATIGUE TEST SPECIMENS (Axial or bending with circumferential groove) Stress concentration influence can be studied with most of these specimens by machining in notches, .ASTM's fatigue and fracture standards provide the appropriate procedures for carrying out fatigue, fracture, and other related tests on specified materials.

This document specifies the method for rotating bar bending fatigue testing of metallic materials. The tests are conducted at room temperature or elevated temperature in air, the .This document specifies the method for rotating bar bending fatigue testing of metallic materials. The tests are conducted at room temperature or elevated temperature in air, the specimen .

Rotary bend wire fatigue is a versatile test that can be used to compare fatigue properties of wires with a wide range of different characteristics including processing method, .Rotating Beam Fatigue testing allows researchers to perform fatigue testing at higher frequencies while saving capital expenses by purchasing a much simpler and more cost-effective test machine design compared to high capacity servo .

torsion test ductile failure

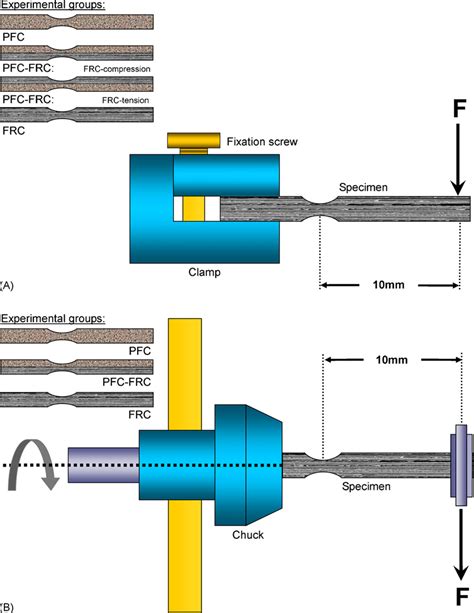

This document specifies the conditions for conducting the plane bending fatigue test on an axial machine, constant-amplitude, force or displacement controlled, at room temperature (ideally . Alternating load fatigue test on metals with adjustable bending tooling.Rotating-bending fatigue testing has become a common test setup for the structural fatigue evaluation of Nitinol wires (Tobushi et al., 1998). Two common configurations of the rotating-bending test setup are shown in Fig. 2. Both types of test setups are used to conduct fully reversed, rotating-bending fatigue.testing has been to use running gear bending fatigue testing, which is also well documented in literature (Refs.1,3,9,10). This type of test uses rotating meshing gear pairs operating under a load, often in a four-square / back-to-back arrangement. The running gear bending fatigue test has the advantage of sub-

with reduced gage section (i.e. hourglass specimen) for rotating bending fatigue test, were designed according to ASTM Standard E-466 [ 13] and ISO 1143 [14], respectively. The specimen dimensions are shown in Fig. 1(a) and 1(b) for axial and . The very high cycle fatigue (VHCF) failure of in-service components is mainly caused by the vibration of thin-wall elements at a high frequency. In this work, a novel model of ultrasonic fatigue test was developed to test thin-wall material in bending up to VHCF with an accelerated frequency. The theoretical principle and finite element analysis were introduced for . The gear bending fatigue test is time-consuming and costly. Hence, an increasing amount of theoretical and simulation work has been carried out. Based on Coffin-Manson criterion and fracture mechanics, Kramberger et al. [14], [15] predicted the 42CrMo4 gear bending fatigue life under different backup ratios. Single tooth bending fatigue testing of gears at elevated temperatures presents some unique challenges, and thus a bespoke solution was required. An insulated steel jig, clad with calcium silicate thermal boards, was designed and manufactured to incorporate a number of heating cartridges - four in total - such that heat would conduct uniformly .

Rotating beam

and also a planned fatigue test suitable for laboratory exercise in a material science or engineering design class was developed. Keywords Fatigue Failure, Fatigue Testing Methods and 4-point bending set-up. Pages 32 p. + appendix

To provide full scale testing of the fatigue performance of our products, Apollo designed, built and commissioned the world’s first large scale rotating bending fatigue tester. Nicknamed the Rotatamatron 3000, the machine is capable of applying a constant stress across a 2.75 in (70 mm) diameter reduced section with a maximum load of 50,000 lbs.Tests can be run at a constant strain level or at a constant stress level. Figure 5 shows the major test equipment. Figure 5: Flexural fatigue testing equipment. Approximate Test Time. Testing time is dependent on the strain level chosen for the test. High strain (400 – 800 microstrain) may be completed in a few hours.The LTM is an electrodynamic testing machine with a drive based on linear motor technology.It can be used for dynamic fatigue tests, as well as for static materials and component testing. The electrodynamic LTM testing machine is used by industries that favor oil free and low noise drive technology, such as the medical and electronics industries/ The LTM additionally offers flexible . A rotating bending fatigue testing machine was developed by keeping in mind the basic concepts of technical theory of bending of elastic beams. Different specimens of 6mm to 8mm diameter of .

Strain-Controlled Fatigue Testing: Description: The strain is controlled instead of the stress, and the material is cycled through specific strains, reflecting operational conditions. Applications: Useful for analyzing the behavior of materials under controlled deformation, like in certain biomedical applications. Corrosion Fatigue Testing:

The aim of this paper is to provide information about fatigue resistance of the TiAl6V4 alloy in the annealed condition at the three-point bending loading test at frequency f∼100.0 Hz [19, 20] with the run-out number of cycles N f in range . Although rotary bend wire fatigue is a relatively common test, the speed used to perform testing can vary greatly. Given that in vivo loading occurs at a much slower rate than the maximum speed of motors used in wire fatigue testers (e.g., approximately 72 beats per minute for cardiac loading versus 25,000 or more revolutions per minute (RPM) for a high-speed .Cyclic fatigue tests produce repeated loading and unloading in tension, compression, bending, torsion or combinations of these stresses. Fatigue tests are commonly loaded in tension – tension, compression – compression and .

In rotating beam fatigue testing applications, a bending stress is applied to a round specimen in constant rotation, causing the surfaces of the specimen see alternating tensile and compressive stresses. This method effectively mimics an axial fatigue test with an R value of -1.

Researchers Groenendijk 1998 and Erkens 2002. proposed pavement life predictions based is using a fatigue relationship that can be obtained by four point bending tests. Fatigue is such test is defined as the number of constant strain applications until the specimen reaches half of its initial stiffness.Three Point Bend Fatigue; Data reported on this test includes load peaks, strain peaks, hysteresis loops at specific intervals, calculated plastic, and elastic strain, first cycle information, and half-life cycle loop information. In addition to axial tests, we also test materials in bending and rotating modes. Bending fatigues could involve .

The testing machine is usually used to test the bending fatigue limitδ-1 of metals under the action of symmetrical repeatedly alternating bending force. Accordingly the tension-compression fatigue limit δ-1p and torsion fatigue limitτ-1 can be determined by calculation according to experienced formula. The system has simple structure, easy . A shaft was rotated under various bending loads which followed the experimental methodology of the R.R. Moore fatigue test. The goal of the experiment was to determine the prediction accuracy .Commonly known as Rotary Fatigue or Bending Moment Fatigue, this test evaluates the wheel's ability to sustain fatigue caused by vehicle cornering. ITS has two types of cornering machines: rotating bending and eccentric mass. Both styles of machine allow for testing up to 26” diameter and 13,000 ft-lb and can be set up to test motorcycle .

The piping component tests which are generally performed to develop fatigue design S–N curves and, subsequently, to determine the stress intensification factors (SIFs) are rotating bending, four-point bending, and cantilever bending tests.Schematics of their test set-ups are shown in Fig. 1.In a rotating bending test, the pipe specimen continuously rotates .

COMMON FATIGUE TEST SPECIMENS (a) Rotating bending, (b) Axial uniform, (c) Axial hourglass These specimens are usually used for axial or bending tests. These specimens usually have finely polished surfaces to minimize surface roughness effects.

This document specifies the method for rotating bar bending fatigue testing of metallic materials. The tests are conducted at room temperature or elevated temperature in air, the specimen being rotated. Fatigue tests on notched specimens are not covered by this document, since the shape and size of notched specimens have not been standardized.

Fatigue Testing Materials Testing to obtain S-Nf Curves is common; several ASTM standards address stress-based fatigue testing. The "Rotating Bending Testing Machine" is similar to the original railroad axle-type Wohler used where the bending moment is constant along the beam length. Each point on the Surface of the Rotating

rotating cantilever beam test

En este artículo, vamos a explorar la plataforma de apuestas 888, que ha ganado popularidad en el mundo de las apuestas en línea. Vamos a revisar los detalles de la .

bending fatigue test|rotating bending fatigue